High Velocity Oxygen Fuel (HVOF)

CabCoat – High Velocity Oxygen Fuel (HVOF) is one of the most commonly used spray coatings, designed to improve or restore a component’s surface properties or dimensions. As a result, it extends equipment life by significantly increasing protection from erosion, wear resistance and corrosion.

The HVOF coating technique allows the application of materials such as metals, alloys, plastic, composites and ceramics to produce a coating of exceptional hardness and outstanding adhesion to the substrate material.

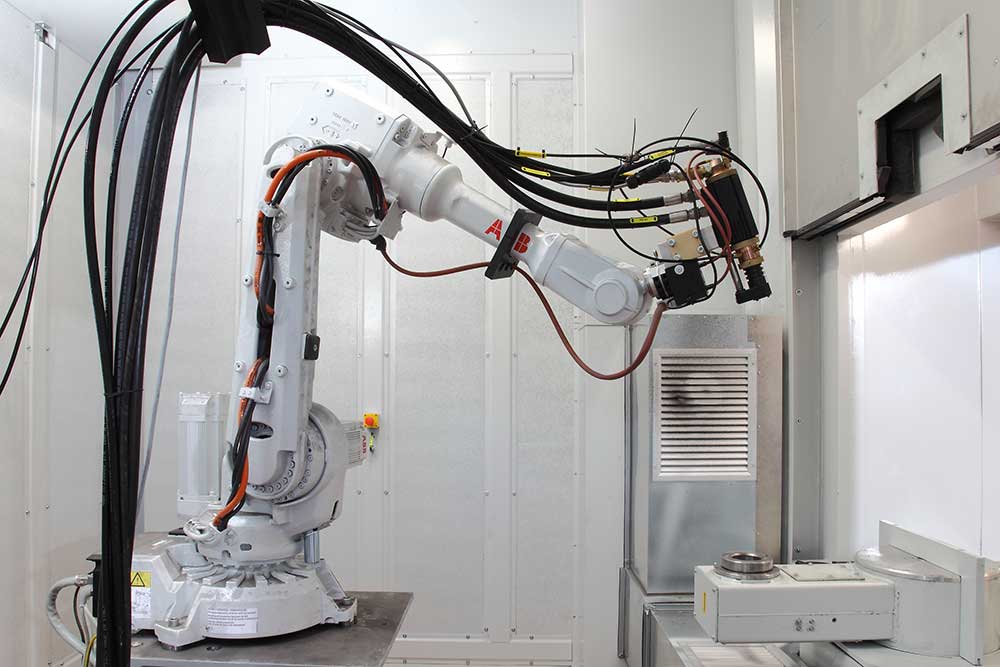

As the technology specialists in HVOF coating, Lincotek Equipment provides an array of spray coating materials to suit your specific needs. Our modular design of CabCoat HVOF offers different coating applications from large to small components.

CabCoat Coating equipment is set up as individual production units or as an integrated part of a complete manufacturing line.

Typical CabCoat equipment consists of core items, handling elements and peripheral components.

Lincotek Equipment offers everything from core items up to peripheral components in one customized package, or as a stand-alone component integrated into existing coating equipment.

| Spray Core | Handling | Peripheral |

|---|---|---|

| Control System | Robot | Booth |

| Gun | Lathe | Ventilation |

| Powder Feeder | Tilting | Filter Systems |

| Power Supply | Carousel | |

| JAM Box |

Main benefits

- Built on experience

- Full closed-loop control of all coating parameters, including mass flow control of the process gases (and fuels) and carrier gases.

- Wide range of materials (Metal alloys, Carbides, blends, Cermets, abradable and oxide ceramics)

- Power distribution unit to power up all peripherals

- Ease of operation and maintenance

- Argon, hydrogen, nitrogen and/or helium as plasma gases

- Wide range of applications

- Compatible with all types of powder feeders

- Everything under control: full integration with heat exchangers, part handling (robot/turn-table/lathe) and exhaust filter systems (power and data exchange)

- Double walled chamber (cooling system)

- Touchscreen operator interface with intuitive visualization software

- Remote maintenance capability

- Sophisticated trending and reporting package

- Realtime monitoring

- Multilevel alarm system and multilevel access

- Storage process recipes

- Loading/unloading of workpieces in a completely automated, one-in/one -out completely automated system Paper