Lean manufacturing, where you share the advantage

Offline robot programming, rapid prototyping and cellular manufacturing. These are the ways in which we respond competitively in the market.

Integrated Supply Chain Solutions

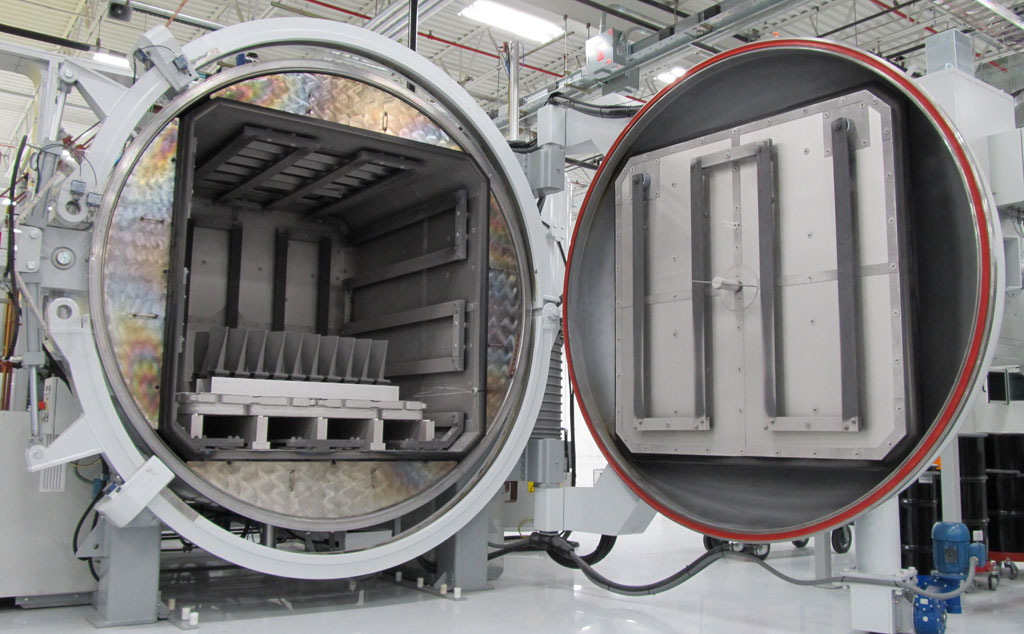

Lincotek Surface Solutions has developed its technology and organisation in order to enhance turbine components and offer a full-range of services to OEM customers.

We deliver effective and efficient services through lean manufacturing techniques, cellular manufacturing, rapid prototyping and off-line programming.We are your single point of service for hot section turbine components. As well as providing Additive Manufacturing, casting and machining processes, we are able to provide the component ready to be installed with our coating treatments and LASER drilling, welding, brazing and NDT services.

Our engineering and production department has the technical expertise to support complex turbine design and manufacturing services, with the goal of producing quality parts in competitive conditions.

Know-how

By merging our expertise in Additive Manufacturing, coatings and related treatments as part of the added value chain, our subject matter experts are able to advise on the interrelationship between each special process. This results in fast and reliable development programmes that reduce overall costs in your supply chain. It also ensures that customer products are brought to market on time, in competitive conditions.

Dedicated team

A dedicated team will take the lead on your program, from the entire development and manufacturing process through to delivery.