/ Titanium anodization

Tihard™

TiHard™ is an electrochemical surface treatment process based on titanium alloy anodization (Type II). It allows to obtain a thick and compact oxide layer that insulates the underlying bulk metal and results in improved mechanical performances and reliability of the final product.

Key facts

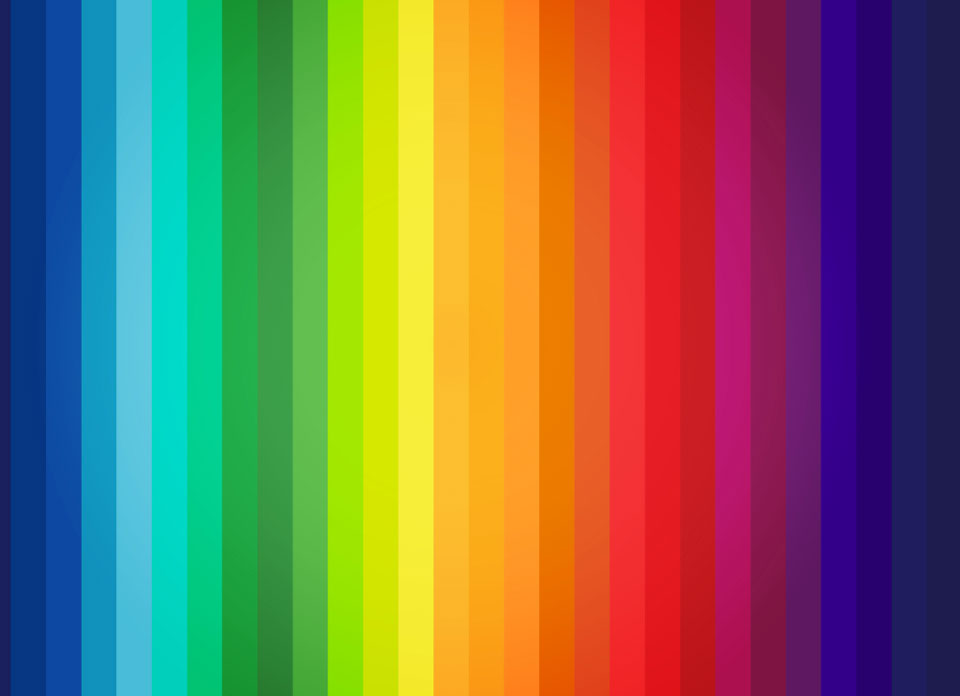

Ticolor™

TiColor™ is an electrochemical surface treatment process based on titanium alloy anodization (Type III). It allows to obtain a thin oxide layer that insulates the underlying bulk metal and results in a wide scale of bright interference colors.

Key facts

Selective™

SelecTive™ is an electrochemical surface treatment process based on titanium alloy anodization (Type III) paired with masking or selective post processes in order to impose/remove the anodization only where required in isolated regions of the part.

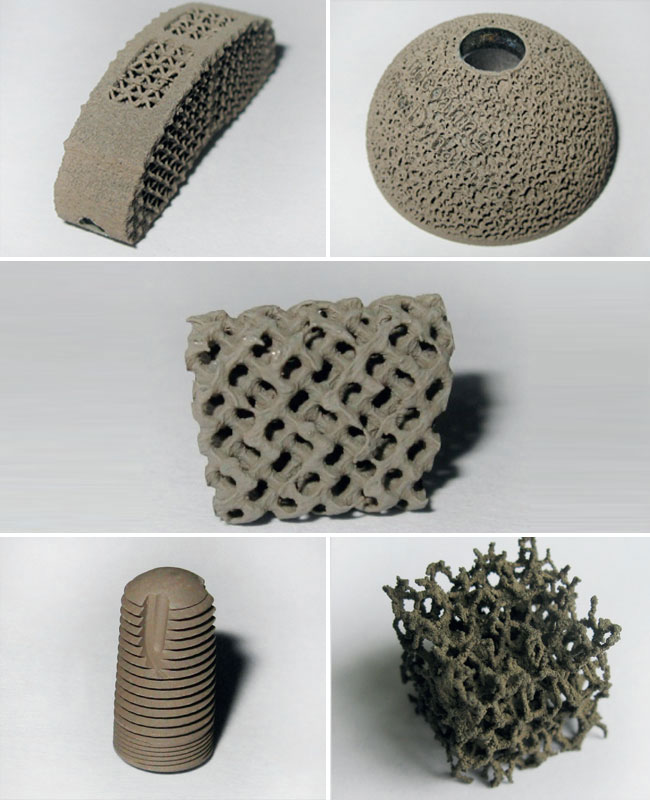

3DGrowth®

3DGrowth® is a patented surface treatment specifically developed for titanium (Ti) substrates. Its unique surface functionalization characteristics enhance and accelerate the osteointegration capabilities of medical implants.

3DGrowth® can be applied to a variety of medical devices, such as:

The final surface features a highly hydrophilic micro-texture. It is composed by a thin anatase layer enriched with calcium, phosphates, silicon and sodium ions.

Compared to the initial titanium surface, 3DGrowth® leads to enhanced cell adhesion, enhanced wettability to biological fluids, improved osteointegration and high mineralization potential.