Mukesh Kumar, Global Technology Director at Lincotek Medical, looks at a recent design success, while unpicking some of the hurdles ahead for the wider adoption of Additive Manufacturing (AM) in the medtech arena.

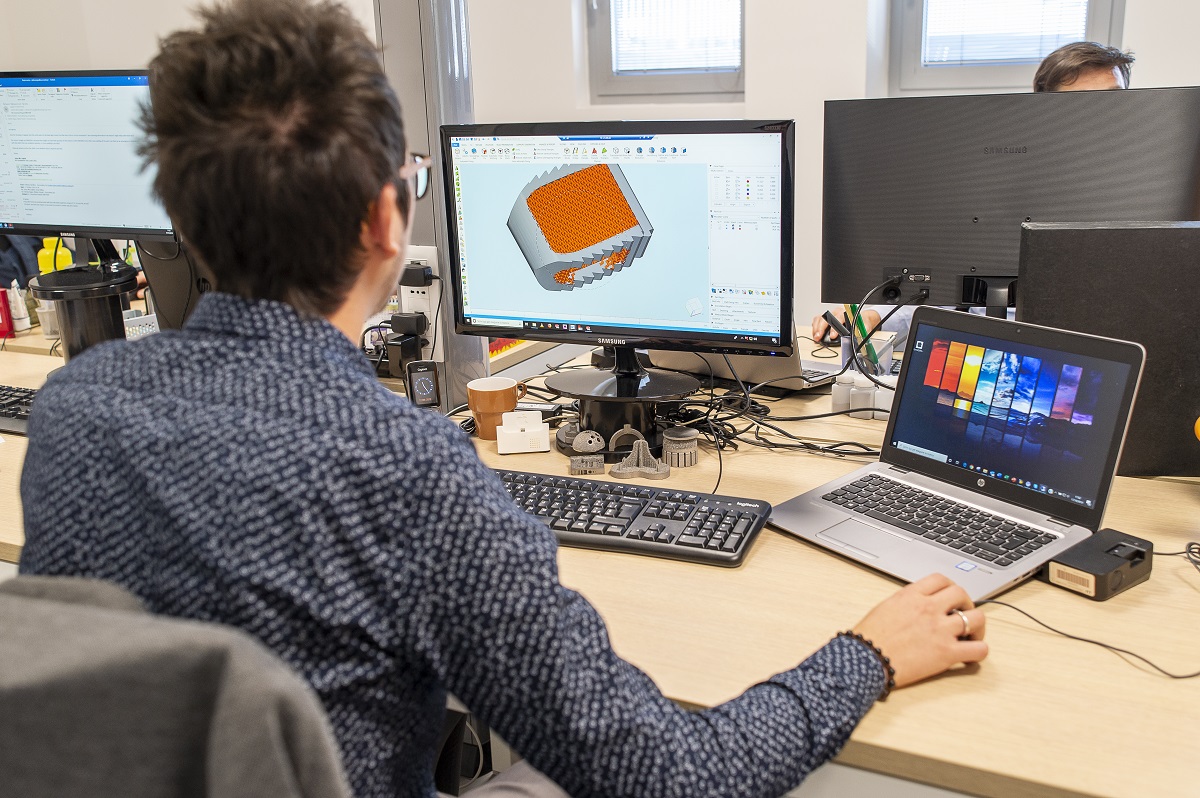

March 25, 2021 | When people ask for an example of a very ambitious AM project, it’s worth considering the work we’ve done recently for one of our customers, which required real design skill. It combined a brushite coating with an AM porous spinal cage. On the one hand, you’re thinking of the implant device and its structural integrity under loading, easy positioning and surface grip and porous structure for both primary and secondary fixation. On the other, you’re concerned with the coating process. It’s a balancing act which calls for real innovation.

But what are the obstacles that prevent the wider introduction of new devices? Well, regulation is right up there – especially in Europe with the new Medical Device Regulation (MDR) – that will be applied from 26 May 2021. Looking further afield, in some countries – like China, to give just one important example – there is still a lack of clear regulation for AM parts. In addition to that, often OEMs are requested to perform clinical trials, which are the highest level in the hierarchy of evidence for a therapeutic intervention, and sometimes this discourages innovation and new tech adoption. Innovations are essential to improve patient care, but they bring with them a responsibility to keep patients’ interests first.

Still, however, the real limitation for larger Additive Manufacturing adoption remains the cost.

Legacy technologies are able to match impressive targets in terms of cost after decades of process optimization. AM has just started to hit this point, while trying to expand beyond specific applications. Competitive AM processes are expected to arrive soon, as raw material qualification, process experience and new tech tools gain momentum. Design for AM, integrated supply chain capability, automation among production steps and smart quality controls will play a critical role in the AM cost reduction, even before brand new AM process adoption.

In the near future, we can expect software to become more and more accurate as it supports modelling and predictive performance analysis during device development. We’re also anticipating faster identification of the best support strategy, improved parts orientation and heat conduction dispersion thanks to AI and machine learning tools. These changes will help enable a “good first run” experience, which will automatically help to reduce costs.

A deep metal, technology and process knowledge has allowed Lincotek Medical to quickly become one of the main global players for orthopedic serial production. Discover more about our additive service offer.