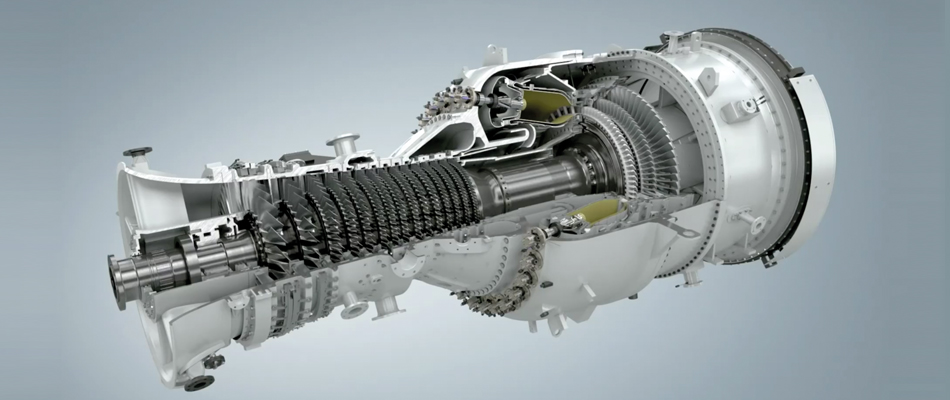

More than a decade of experience in pioneering innovation.

We have championed innovation in additive manufacturing solutions since 2006. Our company has long been at the forefront of research, design, engineering and manufacturing in medical, IGT, aviation and other industrial fields. If your business needs a reliable and sophisticated additive supply chain, our track record is hard to beat. We 3D-printed over 100,000 parts per year with best-in-class yield rates, material consumption and per-unit costs.

Long-term, reliable partnership

As your production grows, we’re there alongside you, investing to support your plans. Our group is family owned and has provided special services to global markets since 1973. We believe in building a reliable partnership that gives you confidence and reassurance to plan for the future.

Leaders in research and development

From two innovation centres – one in Italy, focused on the medical sector and the other in Switzerland, concentrating on industrial applications – we foster a culture of continuous innovation. In addition, we have AM plants and related R&D services in the US and, in the near future, in China too. This enables us to offer in-depth insight and state-of-the-art solutions globally.

Serial additive manufacturing scaled up

We are specialists in scale-up, from part development to serial production. For instance, we are already a global leader in additive contract manufacturing of medical devices, at the lowest scrap rates and best-in-class cost efficiency. We can help you to begin or expand your serial additive manufacturing, wherever you are in the world. But we can go further too.

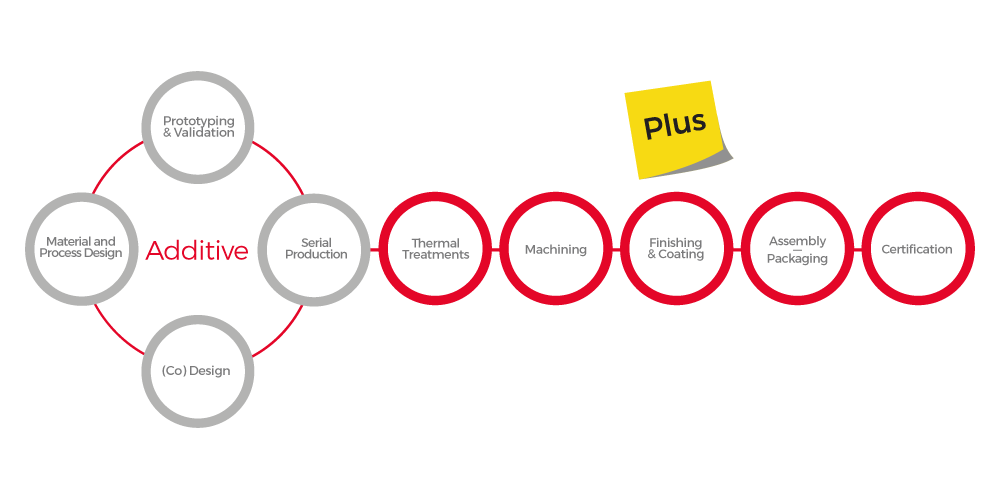

Enabling Additive Manufacturing with post-processing

Post-processing can be one of the key bottlenecks in using additive manufacturing as an industrial process. So, when you have 3D-printed the part, you need to be able to complete it. Post-processing of AM parts is fundamental and truly challenging. It’s this capability that sets Lincotek apart.

As we harness the disruptive power of Additive, we recognise that it is just one step in a much broader process. Our unique portfolio of special processes allows us to offer a complete value chain – starting from printing and going through to thermal treatments and machining, up to surface treatments and final certification. What makes us unique is the integration between the different processes that are already part of the design and development phase.

From Additive Manufacturing to Additive Plus.

It’s the complete additive service offer.

Quite simply, we take you from powder to ready-to-use part and then help you manage the complete supply chain.

We optimize additive metal powders and processes for improved material performance. From design and process development through finished product, we deliver reliable device performance in advanced applications.

With Lincotek Additive, you can rely on short development cycles and significant reductions in time to market too, thanks to our readiness for serial production scale-up and a complete validated process chain.

Critically, we understand how essential a truly integrated supply chain is. That means you can rely on high-quality, on-time delivery and impressive cost efficiency.

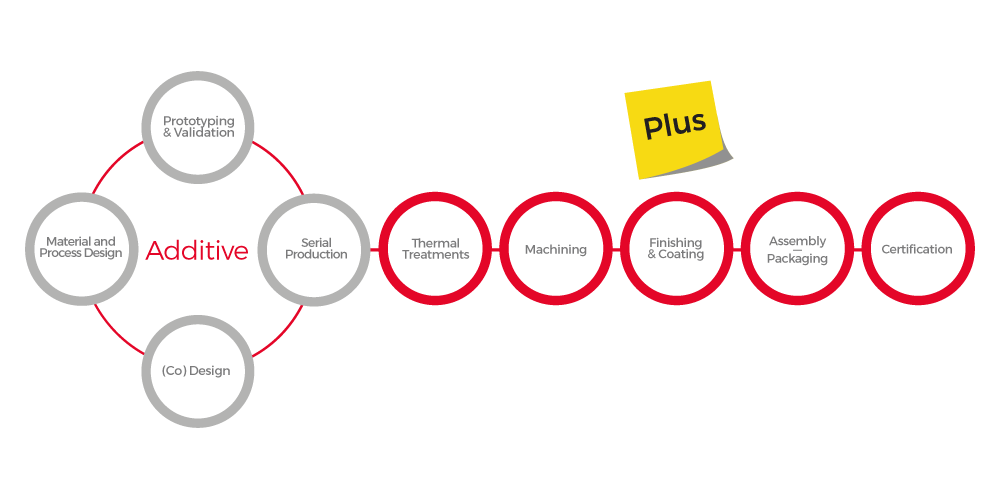

From Additive Manufacturing to Additive Plus.

It’s the complete additive service offer.

Quite simply, we take you from powder to ready-to-use part and then help you manage the complete supply chain.

We optimize additive metal powders and processes for improved material performance. From design and process development through finished product, we deliver reliable device performance in advanced applications.

With Lincotek Additive, you can rely on short development cycles and significant reductions in time to market too, thanks to our readiness for serial production scale-up and a complete validated process chain.

Critically, we understand how essential a truly integrated supply chain is. That means you can rely on high-quality, on-time delivery and impressive cost efficiency.

Built on experience.

Ready for the Future.

Known for guaranteed quality, on-time delivery and cost-efficiency, we have always moved beyond AM to focus on the big picture for our customers. We design, we print and validate, we machine, we finish. Everything in-house. And we’re committed to being a global leader in integrated supply chain solutions.

With Additive Plus, Lincotek is ready for the future. Our printers are never idle and when new opportunities arise to support customers, we’re always prepared to invest.

Today, we’re global in our reach, with the ability to serve any major market. Our European operation is headquartered in Trento, Italy, but we also have a strong presence in Memphis, USA and we are working to build up additive capabilities in our production facility in Wuxi, near Shanghai, eastern China, in the near future.

Lincotek additive at a glance

Materials:

Titnaium alloys such as CpTi and Ti6Al4V, Cobalt alloys such CoCrMo, Steel such as 17-4 SS and AISI316L, Nichel alloys such as HastX; IN625, IN718, IN738 and IN939.

Process Design:

A sizeable R&D team of dedicated engineers working from locations in Italy, Switzerland and the USA, a full range of machines dedicated, and a technology span including laser and EBM with their crucial post-processing capability.

Post-processing:

Massive investments in post-processing for serial production, supporting all the necessary steps after the 3D phase: from thermal treatments to machining; from coating to surface finishing; and from final cleaning to final certification.

Serial Production:

We integrate our additive base capabilities with the post-processing ones to enable true serial additive production with our Additive Plus offer. With production locations in Italy, Switzerland, USA and soon in China, more than 25 machines available and long-term consolidated experience (operations in place since 2007) we have produced more than 800,000 parts since inception.

Quality:

Supported by a team of dozens of professionals, serial production is based on validated equipment and run according to best-in-class scrap rates and OEE (Overall Equipment Efficiency) far above 90%.

In the medical field: plants are ISO 13485 certified and release implantable medical devices (CE and FDA); in IGT/Aviation: main production facilities are certified AS9100/NADCAP

Discover the advantages of our end-to-end additive service offer