Design

From first concept to creating the final technical file, our research and development and regulatory teams have more than extensive experience in developing orthopedic instruments, orthopedic implants, and dental implants, and are ready to support you throughout the design process.

Prototyping

The company is known for its rapid and precise prototyping capabilities – this market critical step is critical to getting innovations to market quicker.

Our Co-Innovation® process is a market leading offering where we partner with not only OEM customers to bring products to market, but also key opinion leader (KOL) surgeons who have an innovative and disruptive product that requires the technical know-how to take it to market.

Additive manufacturing

Our expertise in additive manufacturing is a reliable tool for customers who want to 3D-print medical implants and components. We have succeeded in producing porous structures in, and even inside, very complex solid shapes. We have thoroughly validated and made available for serial production, two of the most intriguing processes available on the market: electron beam melting and direct metal laser sintering.

Casting

Our superior metallurgical experience paired with a passionate and dedicated workforce brings our customers’ vision to market through scale manufacturing. Our centrifugal and static casting, and broad knowledge of key medical-grade alloys allow us to produce implantable medical devices and medical instruments of any configuration and ensure the highest quality end product.

Forging

Our forging facility features a unique, fully-automated, robotized line. We are able to offer a complete forging service, from raw material warehouse management, material cutting and pickling, through to all the different heating and forging steps. From there, we take care of the final heat treatment and parts surfaces – all with unique process control and consistency guaranteed.

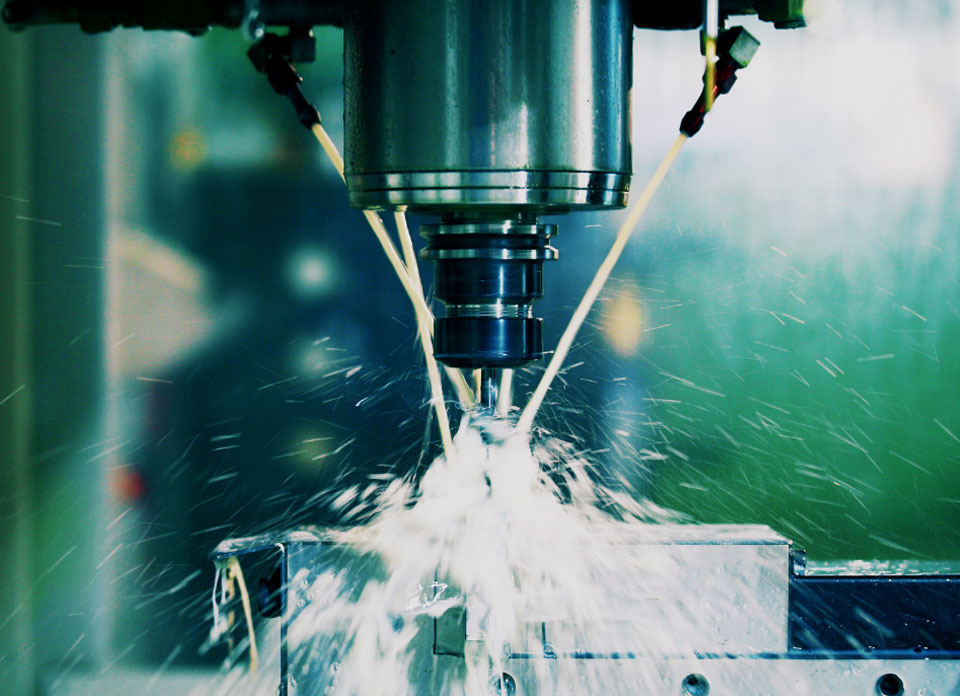

Machining

We combine years of machining craftsmanship along with the newest technology to machine implants and medical instruments. We offer swiss-turning, 3-5 axis milling, lathing, turning and grinding solution to make your ideas become products. We can manage all the supply chain steps for manufacturing hip, knee, shoulder, fixation, trauma, spine, and dental components to give you a complete one-stop-shop solution.

Finishing and polishing

Using the latest robotic technology, we have completely automated processes for finishing and polishing hip, knee, shoulder and other orthopedic implants.

Coating solutions

We offer a range of coating solutions, including plasma spray coatings; calcium phosphate coatings, and physical vapor deposition (PVD) coatings.

Electrochemical treatments

Our electrochemical treatments include titanium anodization and chrome coating. We offer different types of titanium anodization, such as that used to enhance mechanical performance or that used to color the individual parts. Our chrome coating process enables a low-friction surface to be created that improves the service life, performance, and cosmetic appearance of a medical device.

Cleaning and packaging

We take great care in ensuring that our customers’ products are packaged according to applicable industry standards. Our clean rooms are classified ISO 5 and ISO 7.

Additional services

We offer a number of additional services to complement the wide range of products and custom-made solutions we provide to original equipment manufacturers in the medical field.

Spray powder

We manufacture the hydroxyapatite (HA) used in our plasma spray processes in-house.